The firmware update simplifies the handling of the excom I/O system and extends its functionality

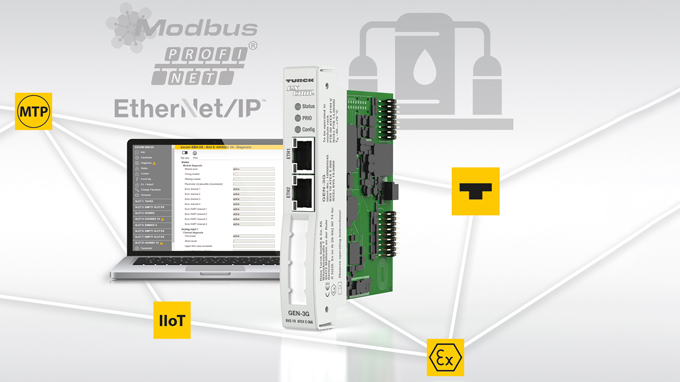

IIoT Functions for excom Ethernet I/O System

Firmware update adds functions such as web server, “HCiR” and parallel access to HART devices to excom Ethernet gateways

The FW 1.6.0 firmware update for Turck's GEN-3G and GEN-N Ethernet gateways for the excom I/O system improves the IIoT capabilities and simplifies system maintenance as well as commissioning. HCiR (Hot Configuration in Run) now also allows device replacement, expansions or maintenance during operation in hazardous areas and high-availability applications. Changing configurations during operation is possible with Ethernet/IP (CIP) or Modbus TCP.

Your Benefits

- Device replacement and maintenance now also in hazardous areas during operation thanks to HCiR

- Simplified configuration and handling of the system via the gateway's integrated web server

Simplified configuration and handling

Turck's new firmware also simplifies the configuration and handling of the system via the gateway's integrated web server. Besides the process and diagnostic data, information such as device type, ID number, hardware and firmware version is displayed directly in the device overview. Direct access to the HART field devices also makes it possible to read out dynamic variables, device IDs, tags etc.

Interconnecting modules of different manufacturers

For easy interconnection of different plant modules from different manufacturers, Turck now also supports Module Type Package (MTP) via its TBEN-L-PLC or TX700 Codesys controllers. Customers benefit from MTP through shorter commissioning times and improved interoperability. The multiprotocol properties of the excom system greatly facilitate the modularization of plants, as the system communicates with all control systems that use Profinet, Ethernet/IP or Modbus TCP.

KEY FUNCTIONS

- Web server for easy configuration and handling

- Display of additional hardware and firmware data

- Direct access to HART field devices

- Easy interconnection of different system modules through Module Type Package (MTP)

- Simplified modularization of plants thanks to multiprotocol features of the excom system

RELATED CONTENT

Video: Predicitve Maintenance in Hazardous Locations

Turck's excom Ethernet gateways transfer selected data to local servers, the Turck cloud or other cloud services, ensuring high transparency and security of IIoT in hazardous areas. Learn more in the video!

Application: Ethernet-based Automation of Modular Skids in Hazardous Areas

Space-saving and easy to combine thanks to ethernet communication

Application: Space-saving Ethernet Signal Connection in the I&C Room

excom-Ethernet enables data-driven process optimization for retrofitting

At a Glance: Safe Use of Ethernet in Ex Areas

Predictive maintenance: Analyze your process data up to zone 0

Technology Page: Ethernet in Hazardous Locations

Technical background information about Ethernet in hazardous locations

PRODUCT DATA

All Details about the GEN-3G Ethernet Gateway

Approvals, data sheets, technical specifications, instructions, certificates, CAD data and more

Select Country

Turck worldwide