Turck Introduces Robust QR24 Sensor for Demanding Applications

Minneapolis, MN - September 29, 2015

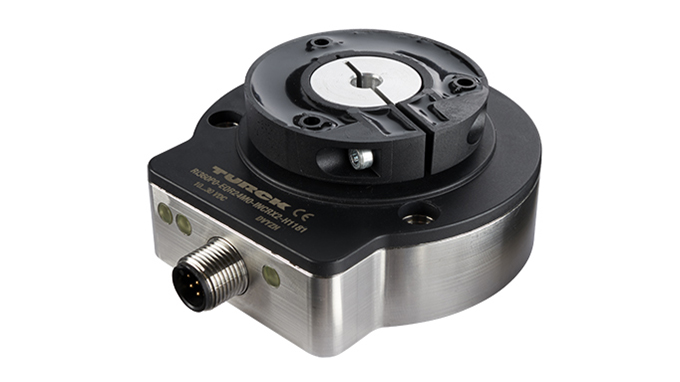

In order to meet the demands of harsh applications, Turck has expanded its QR24 line of contactless rotary position sensors to include a version with stainless steel housing. Available in SSI or with incremental outputs and equipped with 316 stainless steel housing, the new variant is built to withstand harsh environments such as those involving chemicals or high-pressure water sprays. The wear-free performance of the existing QR24 line combined with the stainless steel housing makes the stainless steel QR24 variant an ideal solution for applications that encounter extreme environmental conditions such as in the food and beverage and off highway equipment industries.

The stainless steel QR24 sensor features a fully potted and sealed IP69K/IP68-rated housing to protect against moisture and dust. It also offers flexible parameterization via IO Link or easyteach, allowing the sensor to easily adapt to specific application requirements.

While rotary feedback is crucial in many installations, many rely on their mechanical bearings to provide proper tolerance and position of the internal system. After time, mechanical wear, vibrations, potential leaks in bearing seals, etc. can contribute to premature failure. The QR24 provides customers with contactless position detection, executing the same functions but without the need for contact or bearings, allowing for longer and more reliable solution that saves installation time and costs.

The Turck QR24 series is part of the company’s industry-recognized Q-track family of sensors, which utilize resistance inductive capacitance (RLC) measuring technology. Unlike potentiometric or magnetic technologies, the sensors incorporate precisely manufactured printed emitter and receiver coil systems. The emitter coils are activated with a high frequency AC field and produce an inductive RLC circuit with the positioning element. The element is inductively coupled with the receiver coils, which are arranged so different voltages are induced in the coils, depending on the position of the actuator. The voltages serve as a measure for the sensor signal.

In order to meet the demands of harsh applications, Turck has expanded its QR24 line of contactless rotary position sensors to include a version with stainless steel housing. Available in SSI or with incremental outputs and equipped with 316 stainless steel housing, the new variant is built to withstand harsh environments such as those involving chemicals or high-pressure water sprays. The wear-free performance of the existing QR24 line combined with the stainless steel housing makes the stainless steel QR24 variant an ideal solution for applications that encounter extreme environmental conditions such as in the food and beverage and off highway equipment industries.

The stainless steel QR24 sensor features a fully potted and sealed IP69K/IP68-rated housing to protect against moisture and dust. It also offers flexible parameterization via IO Link or easyteach, allowing the sensor to easily adapt to specific application requirements.

While rotary feedback is crucial in many installations, many rely on their mechanical bearings to provide proper tolerance and position of the internal system. After time, mechanical wear, vibrations, potential leaks in bearing seals, etc. can contribute to premature failure. The QR24 provides customers with contactless position detection, executing the same functions but without the need for contact or bearings, allowing for longer and more reliable solution that saves installation time and costs.

The Turck QR24 series is part of the company’s industry-recognized Q-track family of sensors, which utilize resistance inductive capacitance (RLC) measuring technology. Unlike potentiometric or magnetic technologies, the sensors incorporate precisely manufactured printed emitter and receiver coil systems. The emitter coils are activated with a high frequency AC field and produce an inductive RLC circuit with the positioning element. The element is inductively coupled with the receiver coils, which are arranged so different voltages are induced in the coils, depending on the position of the actuator. The voltages serve as a measure for the sensor signal.

Select Country

Turck worldwide